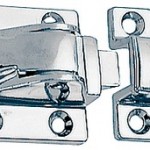

Looking over the cabinet hardware after installing the reassembled cupboard doors, I found the latch hardware was pitted with peeling chrome. Unfortunately the material appears to be chrome on zinc, not brass, so there isn’t much hope for restoring it to any kind of shape. I did a fair amount of internet research and determined that the latches are manufactured by Perko and this is the 3/8″ offset version because the catch mounts on the frame of the cabinet carcass, which is a fraction of an inch below the non-flush door.

Pricing varied pretty widely but I did locate a place that had them at just under $20 a set. This was just before West Marine changed its price matching policy, so I was still able to get them to order up a dozen for me. Seven were available immediately and I had to wait about ten days to get the balance.

- The latches were getting pretty crufty after 25 years. A shot of WD-40 restored most of them to operation but the peeling chrome wasn’t very attractive, and they appear to be zinc castings, not bronze or brass, so stripping them wasn’t an attractive option.

- Seen from above you can see the difference in the mounting between the latch on the left, mounted to the cabinet door and the catch on the right, mounted to the cabinet frame (carcass)

- This illustration shows the difference between the catches used in the 1102DP1CHR at left and 1102DP2CHR at right. The latch mechanism is identical.